Solution / TRENPEX-Portal

Convenient and solution-oriented data access in real time

Our web-based portal gives you full control over all data and information relevant to you—from detailed vehicle views to automated reports and lists.

Web-based User Interface

Precisely tailored and results-oriented

The TRENPEX portal is web-based and can be accessed from any Internet-enabled device, whether PC, notebook, or tablet. Your employees can view deliveries around the clock in real time and check them anywhere in the world without being tied to a specific workstation. This saves time and increases your flexibility in day-to-day business.

Unlike single-user solutions, the TRENPEX portal is designed from the outset for simultaneous, cross-location use by multiple users: This allows different departments such as goods receipt, quality assurance, or accounting to work in parallel in the same system—without data breaks or manual coordination processes.

Our authorization concept and structured access allow you to determine which users or user groups in your company have access to all or only certain measurement data and information. This access control can be reliably and securely regulated down to the lowest information levels.

The TRENPEX portal allows users to create entire reports and lists from the data provided with just one click, such as weighing logs, damage reports, status reports, vehicle lists, and event lists for train and vehicle arrivals and departures. Additional analyses and dictionary functions are also available.

By connecting to any existing systems (REST-APIs, ERP, TOS, AVIS, etc.), your employees are able to work in a results-oriented manner while saving both time and costs.

Below you can find out more about the advantages of the TRENPEX portal:

- Quick overview of locations, measuring points, and individual measurements

- Detailed information on individual vehicles

- Historical data and comprehensive analyses

- Comprehensive status and damage reports

| Web-based user interface for all end devices | |

| Information independent of location and time | |

| Cross-location data usage | |

| Practical multi-user system | |

| Secure authorization concept: Structured access to all measurement data and information | |

| Easy creation of reports and lists (weighing logs, damage reports, vehicle lists, etc.) | |

| Additional analyses and dictionary functions | |

| Targeted connection to existing systems (ERP, TOS, AVIS, etc.) |

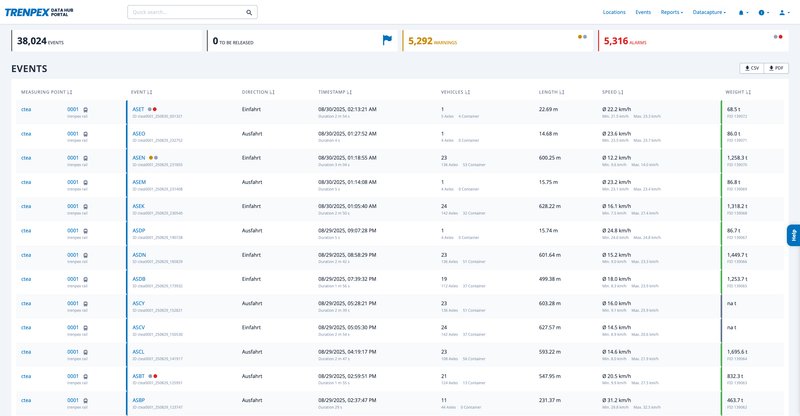

Quick Overview

All measurements at a glance

On the overview page of the TRENPEX portal, you can see all measurement data for the selected measurement location or measuring point. Search functions and filter settings also allow you to search for specific criteria.

Measurements are automatically flagged when minor or major problems are detected, allowing you to immediately identify damaged vehicles or determine whether maneuvering needs to be repeated. For each measurement point, you can specify which anomalies are serious, minor, or irrelevant to you.

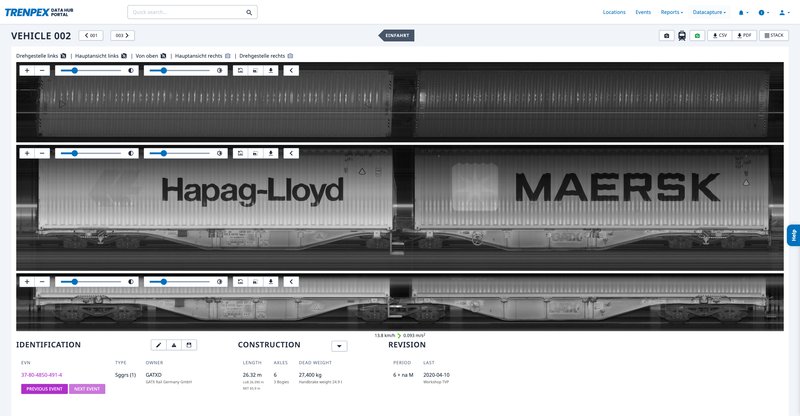

Single Vehicle

Every detail down to the smallest screw

In the detailed measurement view, you will find all information—such as the EVN (formerly also UIC) or the OSJD number of the vehicles, the type designations, the hazardous goods markings, the container numbers, the train length, the train weight, the vehicle weight, and much more—for the respective measurement process.

By clicking on the individual vehicles, you can access further detailed information such as high-resolution images from both sides and from above, the container position in relation to the train head and the front of the wagon, the load limit grid, and the weighing data for the individual axles.

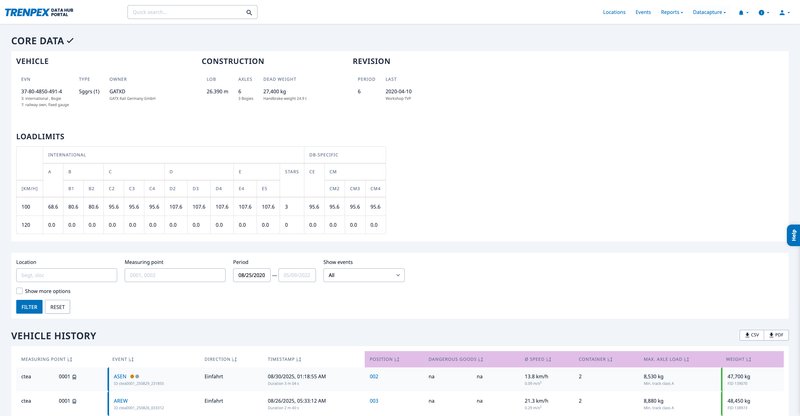

Historical Data

Excellent basis for evaluations

The measurement event data is logged according to your requirements. This allows you to create comprehensive movement profiles and analyses for optimizing capacity utilization, logistics processes, and maintenance of the vehicles used. You can see whether the planned data matches the actual train route, schedule, and car sequence—at the same time, you get a complete historical overview of each vehicle, including loads, damage (e.g., graffiti), and past incidents. Ideal for protecting yourself against fraud and ensuring complete transparency.

Helpful Reports

Greater efficiency through clear data

The TRENPEX portal allows you to create weighing reports for various weighing processes and locations. Our system automatically compares full and empty weights according to your specifications for incoming and outgoing traffic. A permanent real-time weighing list is available to you via the TRENPEX DataHub for downstream systems, ensuring seamless data integration and data flow security.

Our solution also automatically calculates the downtime and idle time for each vehicle on site, providing you with valuable insights into operational efficiency.

In addition, we prepare comprehensive reports as needed in accordance with the GCU, including all labels for wagon owners or the EVU. We support industrial companies with condition and damage reports featuring high-resolution images to enable the defense against compensation claims. This allows you to clearly prove whether damage already existed when the vehicle or container entered or left your premises.

In addition, you can access vehicle and container lists based on individual parameters, along with a complete vehicle and container history of all operations at all connected stations. Furthermore, our integrated lexicons cover a wide range of data, including vehicle owners, vehicle types, hazardous goods markings, NHM codes, core vehicle data, BIC codes, ILU codes, container types, container owners, and organizational codes for container facilities.

Book a live presentation today, free of charge and with no obligation!

We would be happy to show you how real-time data, automated alerts, and seamless integration can help you reduce costs, avoid disputes, and optimize processes. Together, we are sure to find a suitable solution for the logistics processes in your industry.

Get in touch