Introduction

For industrial sites—whether steel mills, chemical plants, or automotive factories—rail logistics is at the heart of the movement of goods, from raw materials to finished products. Yet, while the production processes within the factory are often highly automated, the rail siding outside remains surprisingly analog.

Rising raw material costs, strict safety (HSE) regulations, and the pressure to reduce demurrage fees are forcing site managers to modernize. But the path from manual wagon checks to a fully digitized rail transport processing is rarely clear.

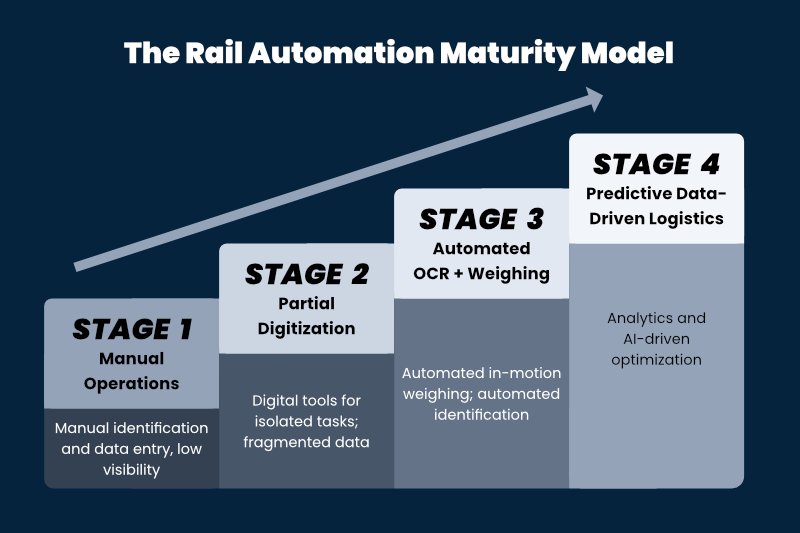

To help industrial operators navigate this transformation, we introduce the Rail Automation Maturity Model as a guide and orientation aid. This framework highlights four stages of operational maturity, helping you identify where your plant stands today and what capabilities and necessary prerequisites you need to secure your supply chain.

Stage 1 — Manual Operations

Low automation, high safety risk, high administrative effort.

At this stage, industrial rail sidings are highly dependent on human intervention. Staff must physically walk along the tracks to check wagon numbers, inspect dangerous goods labels (RID), or inspect seals. Weighing is carried out by uncoupling the wagons on static scales or via so-called weighing jobs on dynamic scales.

Typical characteristics

- Visual inspection: Staff manually writes down wagon IDs and placards.

- Safety Exposure: High necessity for "boots on ballast," increasing accident risk.

- Static weighing: Time-consuming stop-and-go weighing processes or manual weighing jobs on dynamic scales.

- Data lag: Inventory data isn't updated until the shift ends or paperwork is processed.

- Media breaks: Data is collected on paper and then transferred to digital systems, with a high risk of error.

Risks

- Security incidents: Higher risk of injury in the track area.

- Demurrage Costs: Slow processing leads to wagons staying on-site longer than necessary.

- Production Blinds spots: The plant doesn't know exactly what raw materials have arrived until hours after entry.

The Reality: Operators at Stage 1 are often fighting fires, reacting to delayed trains rather than planning for them.

Stage 2 — Partial Digitization

Digital tools are available, but the data remains isolated.

Here, industrial sites introduce isolated digital solutions. Staff might use tablets instead of clipboards, or basic logistics software to track arrivals. However, these tools rarely talk to the central ERP (e.g., SAP). Data is captured faster but remains scattered across spreadsheets, emails, and internal radios.

Typical characteristics

- Handheld Scanning: Reducing handwriting errors, but still requiring human presence on tracks.

- Digital Logs: Weighing data is digital but not automatically matched to the wagon ID.

- Manual Data Entry: Logistics teams still manually type train lists into the ERP.

- Reactive Planning: Shunting operations are planned based on phone calls, not real-time data.

Improvements

- Reduced transcription errors.

- Slightly faster wagon turnover.

Limitations

- Data Silos: The weighing system doesn't "talk" to the inventory system.

- Bottlenecks: Inbound logistics cannot scale to meet peak production demands without adding more staff.

Stage 3 — Automated OCR + In-Motion Weighing

Real automation: The hands-off industrial siding.

This is the turning point for mid- to high-volume industrial sites. Automation takes over the "eyes and ears" of the track. Operators deploy OCR portals and in-motion weighing systems that capture data as the train enters the site—without stopping and without human intervention.

Core capabilities

- Automatic Identification: Capturing wagon numbers, ILUs, and Dangerous Goods labels at speed.

- Dynamic Weighing: Weighing axles and wagons while the train is in motion.

- Visual Condition Recording: High-res imagery for damage assessment (claims management).

- ERP Integration: Validated data flows directly into the plant’s material management system and scheduling system.

- Data persistence: Movements on tracks are stored persistently for traceability and traceability purposes.

Benefits

- Enhanced Safety: Staff stays off the tracks; hazardous materials are verified automatically.

- Billing Accuracy: You pay exactly for the raw material weight received, not the manifest weight.

- Reduced Demurrage: Faster processing means wagons are unloaded and returned quicker.

- Permanent data availability: Train movements are permanently available for statistical analysis and evaluation.

Why this matters: At Stage 3, rail logistics stops being a bottleneck and starts keeping pace with production.

Stage 4 — Predictive, Data-Driven Logistics

Full integration with production and supply chain planning.

The final stage transforms the rail siding into a strategic asset. The system doesn't just record what has arrived; it helps predict and optimize future flows based on historical data and AI.

Capabilities at this stage

- Predictive Maintenance: Detecting wagon defects before they cause derailments or delays.

- Just-in-Time Integration: Rail data triggers production workflows automatically.

- Automated Anomaly Detection: AI flags overloaded wagons or mismatched dangerous goods labels immediately.

- Sustainability Reporting: Automated CO₂ tracking for corporate ESG (Environmental, Social, & Governance) goals.

Impact

- Maximum Uptime: Raw material supply is transparent and predictable.

- Cost Leadership: Minimized demurrage, optimized shunting, and precise billing.

- Full Traceability: A complete digital audit trail for every ton of cargo entering or leaving the plant.

How to Determine Your Plant’s Current Stage

Ask these questions regarding your raw material intake:

- Do staff still have to walk the tracks to identify wagons?

- Is weighing a bottleneck that requires stopping the train?

- Does the production team know exactly what vehicles are on-site in real-time?

- Are we paying demurrage fees because of slow processing or administrative lag?

Your answers will place you clearly into one of the four stages.

How TRENPEX Helps Industry Advance

TRENPEX is engineered to move industrial sites from manual reliance to full automation. We understand that in a chemical plant or steel mill, reliability and safety are non-negotiable.

Key Industrial Capabilities

- High-Accuracy Rail OCR: Reads dirty, damaged, or obscured wagon numbers typical in bulk freight.

- Hazardous Goods Detection: Automatically reads and verifies RID plates for safety compliance.

- Precise In-Motion Weighing: Validates raw material quantities for accurate invoicing.

- Seamless Integration: Pushes clean data directly to your ERP, bridging the gap between logistics and production.

- Persistent data storage: Train movements are permanently available for statistical analysis and evaluation.

Conclusion

The industrial sector is digitizing rapidly. Understanding your place in the Rail Automation Maturity Model helps you identify the operational gaps that are costing you money and safety risks.

Most industrial sites are stuck between Stage 1 and Stage 2—reliant on spreadsheets and manual checks. The most efficient plants are already in Stage 3, securing their supply chains against disruption.

The question now is: Is your rail siding an operational bottleneck, or a competitive advantage for your production line?